PLAN

GET STARTED PLANNING YOUR SPACE

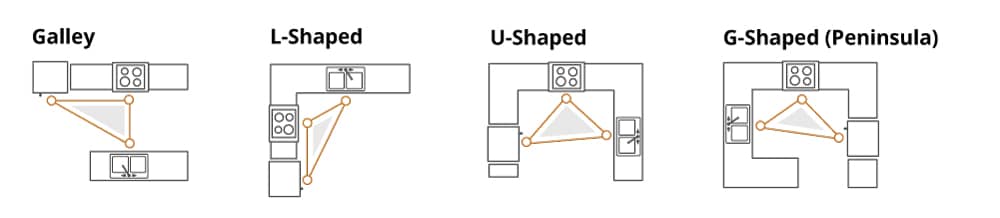

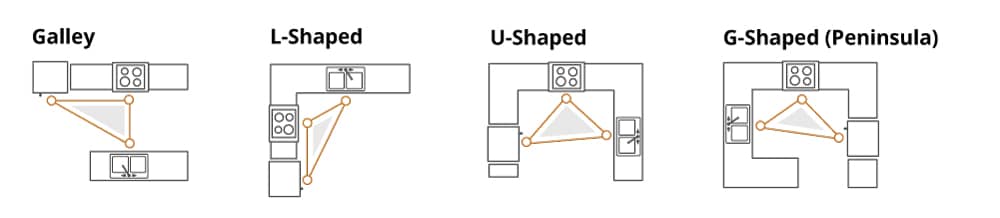

The working triangle should be the foundation of your kitchen design. It is made up of imaginary lines connecting the three most utilized areas of your kitchen – where you cook, where you clean and where you store your food – that is, your range, sink and refrigerator. Keep these three guidelines in mind to get the most out of your space:

- Avoid obstructions in the way of your working triangle – most experts suggest no more than a 12 inch obstruction.

- Note the distances between your work space items to ensure they are neither too close nor too far from one another — most kitchen designers recommend 4 to 9 feet between each point of the triangle.

- Consider foot traffic in your kitchen. A bustling home with lots of foot traffic in your working triangle is just a moving obstruction.

Kitchens generally have one of four shapes: Galley, L-shaped, U-shaped, or, (with the inclusion of a peninsula) G-shaped. Your cabinetry decisions will be based on this shape and your knowledge of your working triangle.

- Galley kitchens provide an efficient cooking area without taking too much space – smart organization cabinetry and above-counter cabinetry ensures a place for everything.

- L-shaped kitchens ensure minimal foot traffic and are an excellent candidate for island counters. Cabinetry is heavily showcased with this style kitchen, so be sure to select a door style and finish that makes a statement and compliments surrounding decor.

- U-shaped kitchens surround the cook with appliances and cabinetry. Intentional utilization of corners with smart cabinetry organizers expand space even more, keeping everything conveniently accessible.

- G-shaped kitchens use a peninsula to tie the dining and kitchen areas while providing extra counter space. Consider attention-grabbing upper cabinets to draw eyes upward, enlarging your space.

- The addition of an island to any of the kitchen shapes can make your work zone more efficient if space allows.

Because Woodland builds each cabinet upon order, our process begins when yours does. This means you get full control over how each piece is made, but it also means our cabinetry isn’t shipped overnight from a warehouse. Our cabinets are manufactured from the highest quality materials and our skilled craftsmen apply finishes by hand.

Because the time for cabinets can vary largely based on the specifications chosen as well as the number of cabinets, we can partner with you each step of the way. Once customers have decided what they want, most projects take anywhere between 4-6 weeks to manufacture with additional time required by your installer.

There’s no denying kitchen remodels are expensive. While stock cabinets are the most economical, much is often sacrificed in the overall quality and aesthetic of your room. Especially in the kitchen — the heart of your home.

Real Estate experts say that spending 8-12% of your home’s value on a kitchen remodel will be returned upon the sale of the home. In a kitchen remodel approximately 60%-70% of the total cost is product and 30-40% is labor. In a bath remodel, the labor percentage is usually equal to or higher than the product portion. In a kitchen remodel the three main categories are cabinetry, appliances and countertops. Cabinetry is not the category to cut back on as it’s the most expensive to replace. Less expensive appliances or countertops can more easily be replaced a few years down the road if the estimated remodel exceeds the budget.

At Woodland, we’re dedicated to providing affordable custom cabinetry that fits your unique vision. We partner with homeowners, scaling features to align with your budget. Choosing custom cabinetry allows you the flexibility to get everything you want — and nothing you don’t.

We promise to be transparent and reliable to help you along each step of the way.

From order entry to delivery, Woodland Cabinetry is proud to provide cabinetry that brings your dream home to life. Here’s how we work:

Woodland manufactures custom cabinetry for every room in your home at an affordable price. We don’t stock standard inventory, so every order is built custom to your needs. Starting with kiln-dried rough lumber, your custom kitchen cabinetry is processed in our Sisseton, SD factory with strict quality standards. But more importantly, your cabinets are manufactured by employees that take pride in their work.

All our processes are designed and executed to instill the highest quality possible into your cabinetry. Our factory uses state-of-the-art equipment to ensure optimal material utilization and accuracy while significantly minimizing waste and protecting our world’s natural resources. We standardize work practices to ensure consistent results and cost-effective construction. Additionally, all our finishes are hand-applied by highly-skilled craftsmen, guaranteeing a handcrafted look for yet another personal touch to make your kitchen uniquely yours.

Throughout your entire process, Woodland Cabinetry and our dealer partners are right here to ensure your satisfaction. Our team is friendly and accessible, with the know-how to answer your questions about every step of your project from design and ordering to construction, delivery and follow up.